Home > News

-

Product instrumentally plan

26/09/2022 -

Localization of medica equipment in China

01/06/2022 -

Pulpping Process

20/04/2022 -

NEW Product Intuition 9 Series Controller

11/04/2022 -

Exhibition Plan 2022

22/01/2022 -

Code of Practice for Fresh Water Cooling Towers

02/11/2021 -

Server Immersion Cooling

04/08/2021 -

Tuen Ma Line Commences

07/07/2021 -

Announcement

03/03/2021 -

Link

25/12/2020 -

IWAKI Pumps (Shenzhen) Co., Ltd.

25/05/2020 -

Updated ISO 140001 Cert.

14/02/2020 -

Announcement

02/10/2019

Pulpping Process 20/04/2022

In digital era, paper products have been transformed into environmentally friendly materials due to their biodegradable properties. The principle of papermaking is very simple actually. Even in modern papermaking, the process is not much different from the original, just replaced by machine.

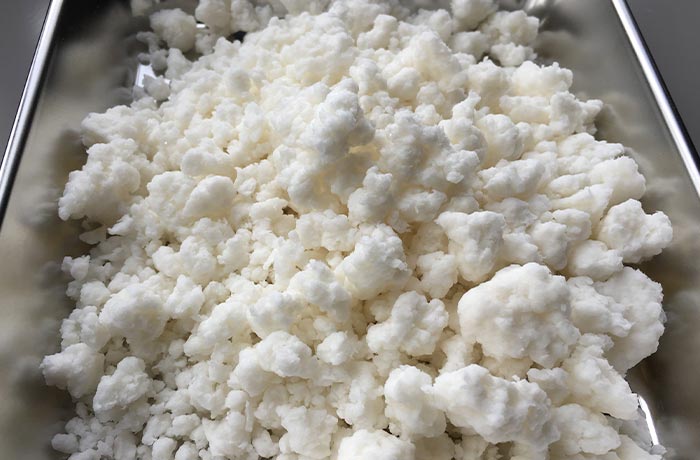

Papermaking can be mainly divided into two stages, namely pulping stage, and papermaking stage. According to the final requirements, coating and processing stage can also be added later. The first stage is pulping, which includes digestion, washing, screening, and bleaching. The major material of pulp is raw wood, recycle paper can also be recycled and disintegrated into pulp again. After the pulpwood is peeled and chopped, the wood chips will be treated with chemicals such as sodium hydroxide and sodium sulfate under the high-pressure environment in digester for delignified.

The washing process requires the addition of sodium hydroxide and chlorine for deinking. The bleaching process is required the use of sodium hypochlorite, hydrogen peroxide and chlorine dioxide for bleaching and improvement of brightness.

Several chemicals are also used throughout the processes. For example, it is necessary to add enhancers, degassing agents, defoamer, flocculants, etc. According to the requirements of the finished product, there are also needs to be sizing to enhance the anti-permeability or adding talc/titanium dioxide/gypsum/clay to enhance the optical effect of the pulp, etc.

.jpg)

Digester

Black liquor is a by-product from the pulping process. It is mainly the aqueous solution of lignin residues decomposed from the pulpwood during the digesting process, and the organic chemical and inorganic substances. Black liquor should not be discharge directly. It would be combusted with sodium sulfate in recovery boiler and obtained molten salts ("smelt"). Then it is mixed with the calcium oxide, which is obtained by calcining calcium carbonate, and become calcium hydroxide in solution to regenerate white liquor used in pulping process.

The pulp will be water drains off and dried as a sheet of pulp for the further papermaking stage.

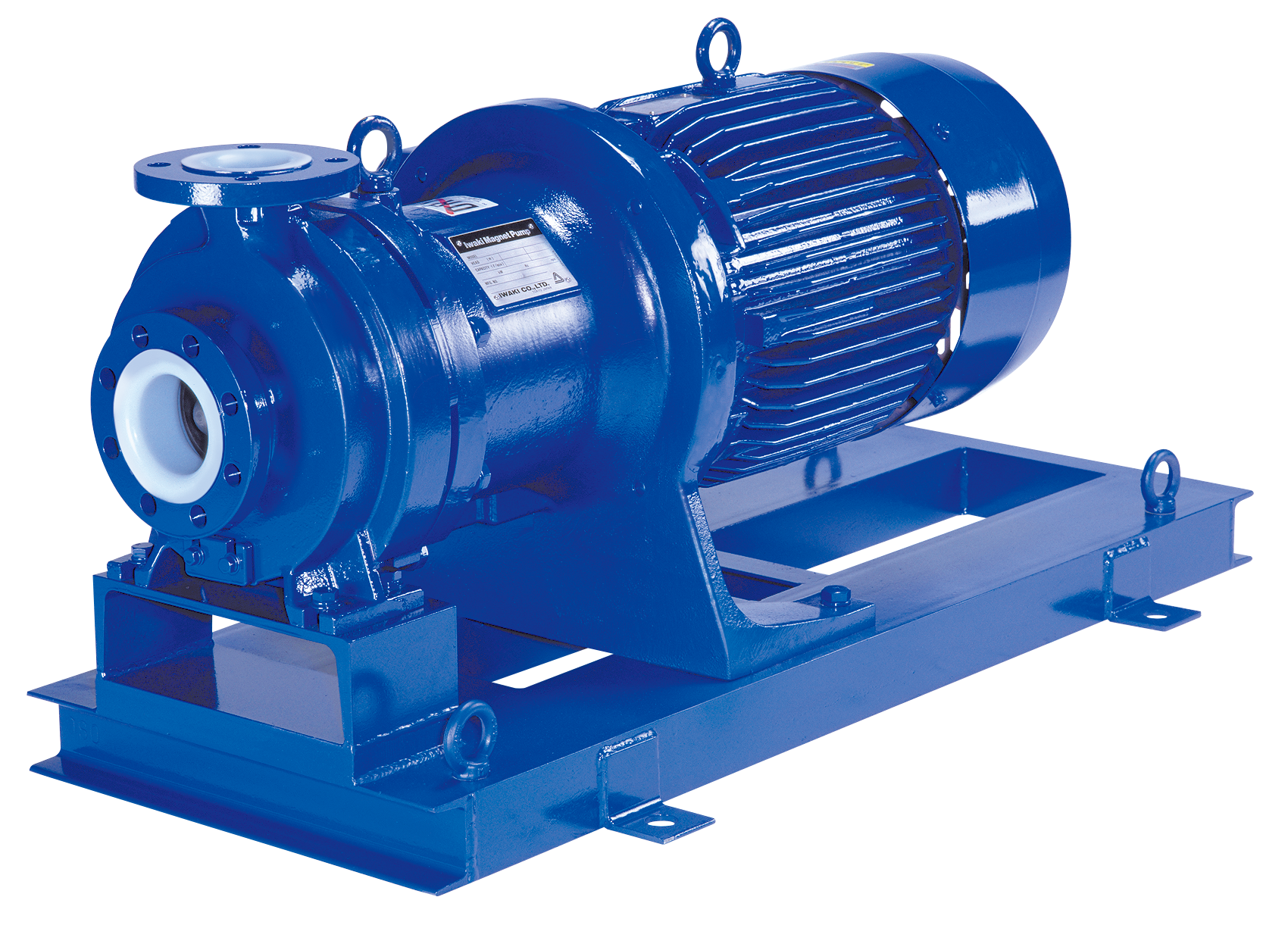

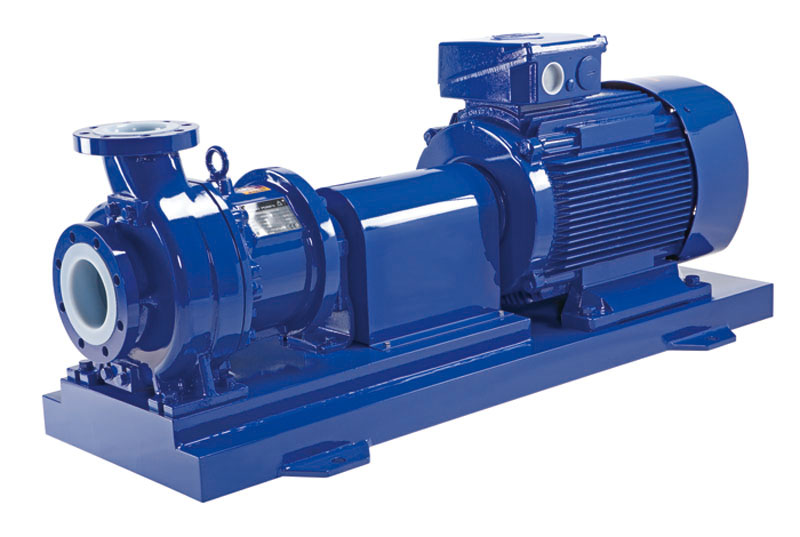

The MDM series features a unique mechanism which gives a greatly improved performance against dry running. Applications cover a wide range of chemical process duties from acid to alkali together with high purity chemicals.

Carbon fiber reinforced CFRETFE and PFA linings can be supplied to meet many varying duties. PFA being a natural unfilled material generates fewer contaminants and makes it ideally suited for transfer of high purity chemicals.

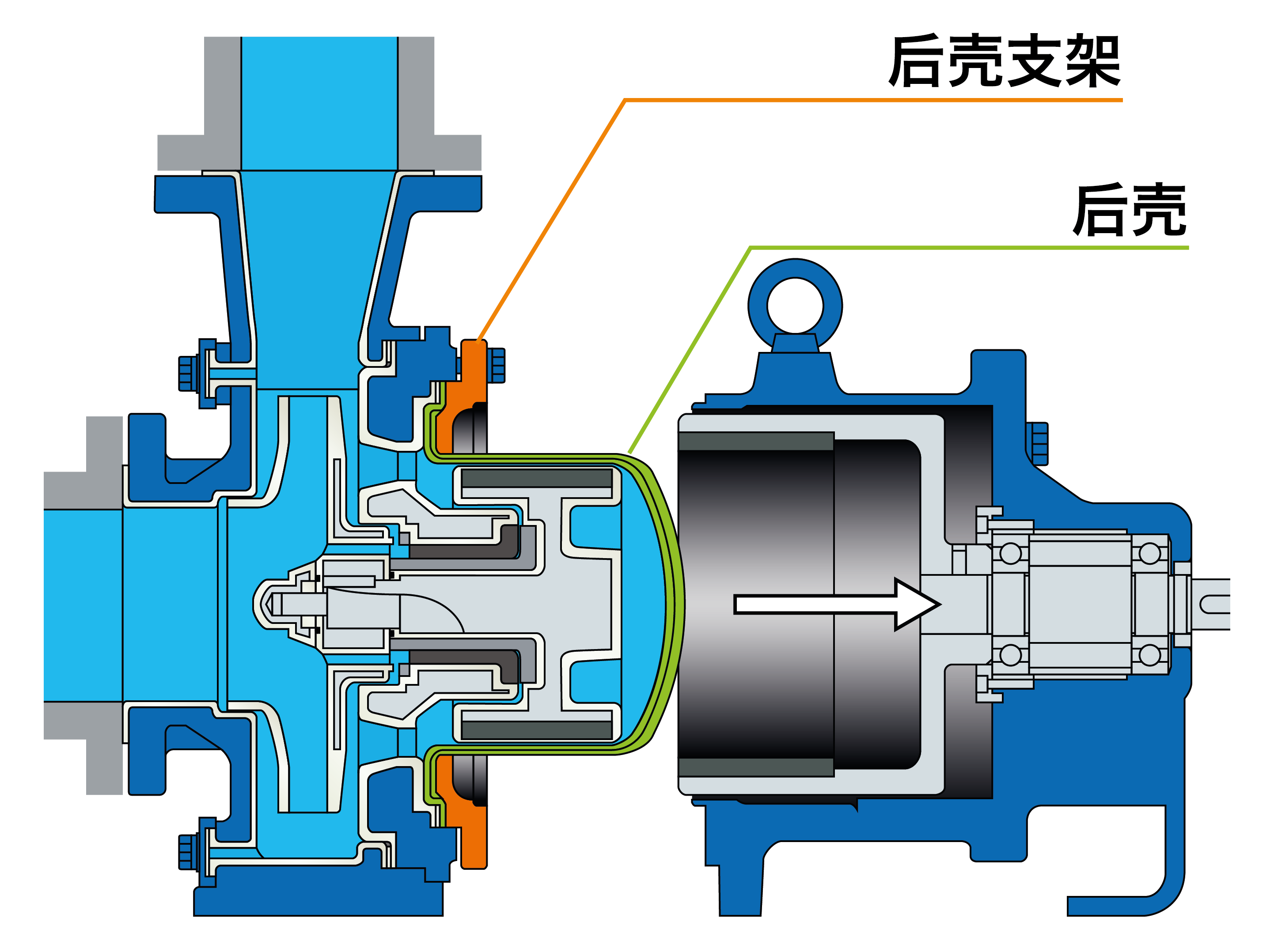

Even if the bracket is backpulled, the rear casing is fixed with the rear casing support and bolts to the front casing side, so there is no leakage of the used liquid. A 2-step disassembly structure that considers safety.。

IWAKI heavy-duty magnetic pump series has included the world's largest class fluoroplastic magnetic pump MDW series.

Please follow IWAKI China official account to receive our latest information.

粤公网安备 44010502002553号

粤公网安备 44010502002553号